Our Equipment List

To keep our customers ahead of the competition, Troy Laser & Fab uses the most advanced and highly productive laser cutting and fabrication equipment.

With this assortment of Laser Cutting and Fabrication Equipment our lead times are shorter than the industry average.

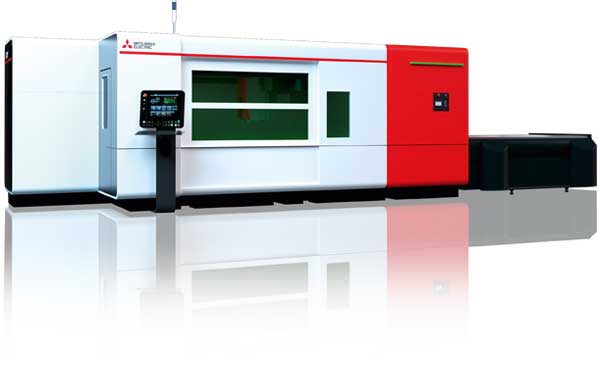

Mitsubishi ML3015 Fiber Laser

- 8kw

- 60″ x 120″ max sheet size

- 1″ mild steel max thickness

- 1” aluminum max thickness

- 1“ stainless max thickness

- 9/16″ brass max thickness

- 1/2″ copper max thickness

Mitsubishi ML3015 C02 Laser

- 4.5kw

- 60″ x 120″ max sheet size

- 1” mild steel max thickness

- 3/8” aluminum max thickness (feature size no smaller than material thickness)

- 1/2” stainless max thickness

- ±.004 up to 11 ga

- ±.005 up to 1/4”

- ±.008 up to 3/8”

- ±.010 up to 1/2”

BLM LS5 Fiber Laser

- 6kw

- 5/16″ Mild Steel (N2)

- 5/16″ Mild Steel (Air)

- 1″ Mild Steel (O2)

- 1-3/16″ Stainless Steel

- 1-3/16″ Aluminum

- 19/32″ Aluminum (Air)

- 15/32″ Copper

- 25/64″ Brass

BLM LT7 Fiber Tube Laser

- 3kw

- Round tube from .5” – 6″

- Square/Rectangular tube .5” – 6” Max diagonal of 8.5″

- Mild steel – stainless steel – aluminum – other alloys

- Mild steel max thickness- 5/16”

- Stainless steel max thickness – 1/4”

- Aluminum max thickness – 1/4”

- Copper max thickness – 1/8″

- Maximum bundle weight of 11,000 lbs

- Maximum bar weight of 15.4 lbs per foot

BLM LT8 C02 Tube Laser

- 3.5kw

- 3D-8.5 – 6.5 (cut 90 to face)

- 0.5″ – 8.5″ Round Tube Diameter

- 0.5″ – 8″ Square Tube

- 0.5″ – 8″ Rectangular Tube

- 8′-2″ – 27′-10″ Rear Automatic Bundle Loader

- Front single Bar manual Loader

- 21′ – 3″ Finished Part Unloader

- Front Unloader Parts Conveyer (Parts up to 19″ Long)

- Mild Steel max thickness 1/2”

- Stainless Steel max thickness 1/4”

- Aluminum Alloys max thickness 14 GA

- 8.2″ Minimum Bar Load Length for Automatic Loading

- Maximum tube weight of 23.5 / foot

Coherent Metabeam 400 watts

- Max Sheet Size 4’x8’

- Material it can cut

- 3/4” Plastics

- 3/4” Rubber

- 3/4” Wood-based materials

- Paper

- cardboard

- Fabrics

Accu-kut 400 amp

- 400 amp plasma cutter

- Max sheet size 75” x 144”

- Mild Steel max thickness 3”

- Stainless Steel max thickness 2.5”

- Aluminum max thickness 2.5”

- Bevel Cutting capabilities 0 degree to 45 degree of max thickness

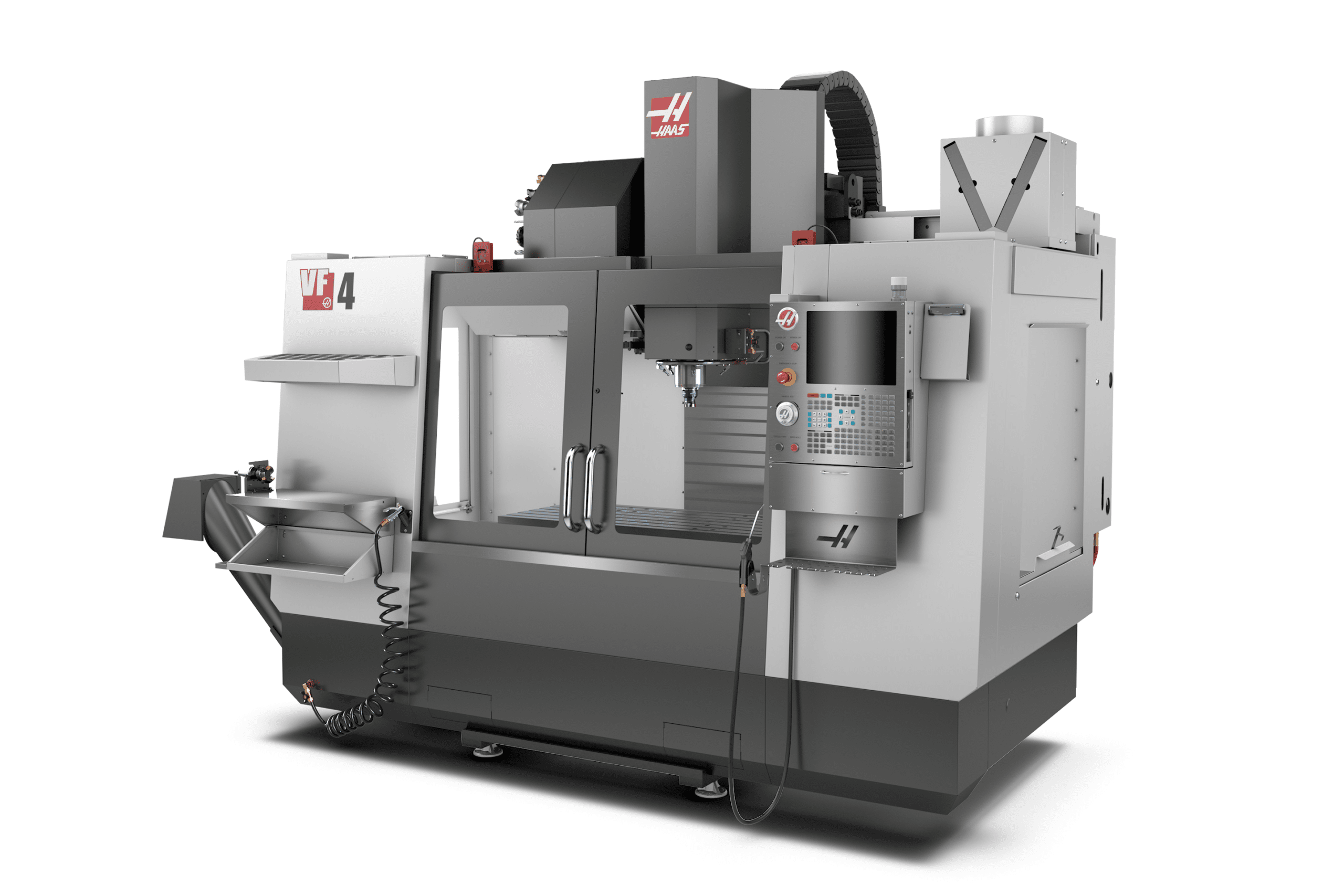

Haas VF4 Milling Machine

- High-Power Inline Direct Drive

- 8100 rpm Spindle

- 20 Pocket Carousel Tool Changer

- Window Air Blast

- Liquid Cooled

- Travels

- X Axis of 50″

- Y Axis of 20″

- Z Axis of 25″

Haas VF2 Milling machine

- High-Power Inline Direct Drive

- 8100 rpm Spindle

- 20 Pocket Carousel Tool Changer

- Window Air Blast

- Liquid Cooled

- Travels

- X Axis of 30″

- Y Axis of 16″

- Z Axis of 20″

BH 25030 Press Brake

- Bending Capacity 250 Ton

- Bending Length – 122″

BB 6020 Press Brake

- Bending Capacity 60 Ton

- Bending Length – 83″

MICRO-BEND CNC Hydraulic Press Brake

- Bending Capacity 40 Ton

- Bending Length – 39″

Lissmac SBM-LI500G1s2

- working width max 1500mm

- workable material thickness 0.5-50 mm (0.02-1.97 inch)

Lissmac SBM-XS300G1e1

- working width max 300mm

- workable material thickness 1 – 15 mm (0.04-0.59 inch)

Ercolina 3

- Mild steel tube capacity 3” – .065 wall

- Pipe Capacity 2-1/2” Sch 10

- Square tube Capacity 2”

Roto-Finish 050” Vibretory Bowl

Max working Capacity

- 11 cu.ft

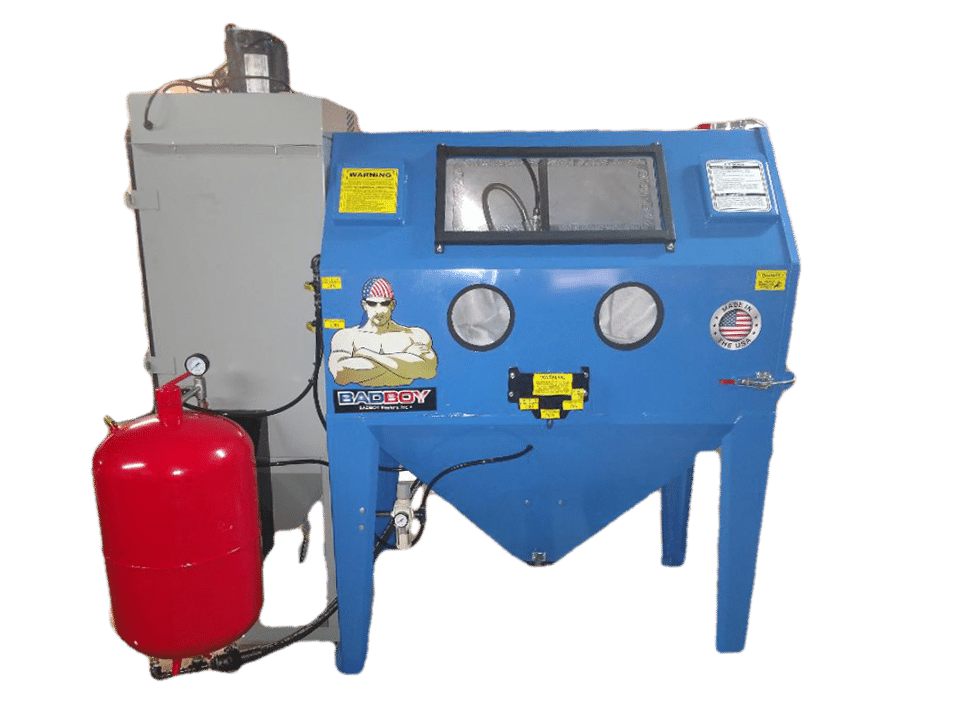

Badboy media sand blaster

- Work area is 48” x 29”

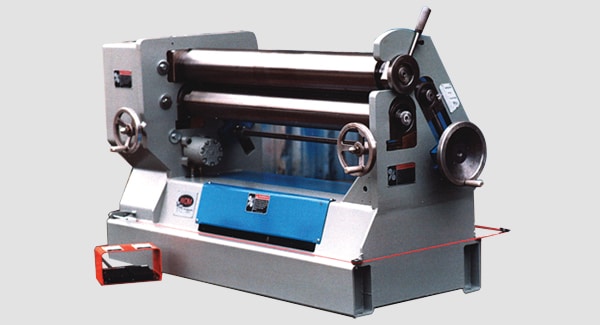

WDM B-05” x 60

Specifications

- Workable Service is 60”

- Max plate thickness is ¼” at 6” wide

- Smallest Diameter is 6”