Cutting Techniques

When it comes to manufacturing and cutting, tradesmen are continuously looking for techniques and technology that can help them work more efficiently, effectively, and economically. Laser cutting, which has recently been gaining popularity, offers businesses the chance to capitalize all three. Since the first lasers were developed in the mid 20th century, the ability to use them to for a wide range of applications has continued to improve. There are a number of benefits lasers can offer businesses looking to improve their products and services and grow their companies.

Improved productivity

Lasers are capable of working both quickly and accurately. While work rate depends on the metal’s thickness, material, and the type of lasers, the system does work considerably faster than many other cutting systems. Lasers are also accurate, which allows tradesmen to work effectively. When work is completed more quickly, businesses are able to improve their revenues. Lasers also do not require contact with the metals they are manipulating, which helps to minimize wear and tear on the parts.

Low heat

Lasers have highly concentrated output that also travels at very high speeds. High speeeds help reduce potential heat related damage to the rest of the metal being cut. The high speed makes it easier to do jobs such as cutting a metal container together without damaging any components within. Low heat and concentrated output helps improve the accuracy of the final product. Low heat also helps reduce the amount of smoothing and finishing work that the professional must to do the product after cutting.

Automation

Lasers lend themselves easily to computer automation. Tradesmen can program computers to cut or weld particular materials with exact measurements. The computer improves accuracy to a greater degree while also making it easier for a well equipped shop to finish more jobs without needing to hire additional workers. The jobs are also easy to transmit from automation to manual, which can help with needed changeover.

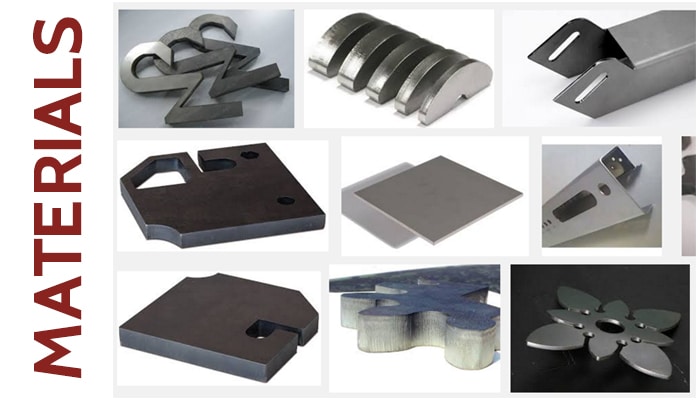

Wide range of applications

Lasers can be used in numerous different jobs, including cutting, welding, drilling, engraving, and structuring. Lasers’ versatility makes it easier for shops to become well rounded and provide a range of services for customers. Lasers are also capable of reaching a variety of difficult areas that other welding or cutting techniques cannot access, making lasers a valuable resource everywhere. Laser welding can cut so deeply that other welding processes often cannot replicate it.. In some situations, therefore, lasers are the only option.

Low clean up

There is minimal cleanup that needs to be done following laser work. A minimal amount of smoke occasionally forms, but there is very low risk of noise pollution or danger. There may be a little vacuum extraction to remove dust during the process, but the final cleaning needed is very little. This reduces the need for additional work related to each job.

Laser cutting is quickly becoming one of the premier manufacturing methods because of the many benefits it offers businesses. From automation to improving productivity, businesses have many potential areas where they can gain.