Elimination of tooling. Improved accuracy. Savings to the bottom line.

Those are just three of the benefits of using 2D laser cutting, a fast, digital, streamlined process that can be used for both rapid prototyping, engraving and manufacturing purposes. To quickly review, 2D laser cutting is a process that uses a high-powered, thin, concentrated laser via computer numerical control (CNC) to either melt, burn, vaporize or blow away a material, thereby leaving an edge with a very high-quality surface finish. In industrial applications, 2D lasers are commonly used to cut the likes of piping and sheet metal, and the process is also utilized in educational environments, as well as by businesses and hobbyists.

So just why does 2D laser cutting make sense for your next project? The reasons are plenty – here’s a look at some of the benefits of using this process versus other manufacturing processes:

Lasers are one of the coolest technologies on the planet

Until recently, most people thought laser cutting was largely only in the hands of scientists, doctors (eye surgeries), and other specialized technology types. Much of the billions in this statistic are made up of large systems for large manufacturers, but many maker companies know the value of a laser cutter or laser engraver. They are far more accessible these days and companies like Troy Laser are ready to help. We are in the midst of making things with it and learning a ton about laser cutting and engraving.

- No tooling: One of the biggest benefits of 2D laser cutting is how streamlined the process is. There’s no need to create expensive tooling for prototyping or manufacturing purposes, which thereby allows product designers to make faster changes and keep production on schedule. Not only is tooling expensive, but the lead times associated with creating tooling can be lengthy, sometimes taking as long as several weeks. And, of course, when tooling and dies are necessary, companies have to dedicate space in their facilities to store such materials. The lack of tooling, and minimal downtime involved in the process, also means that it’s an inexpensive process when compared to others – and it’s these cost savings that go directly to a company’s bottom line or can be passed on to the customer.

- High accuracy: One big advantage that 2D laser cutting has over other manufacturing methods, such as die cutting, is its high level of accuracy. With that being said, the process is an ideal one for applications with tight tolerances or sizes or other characteristics that would pose problems for conventional die cutting.

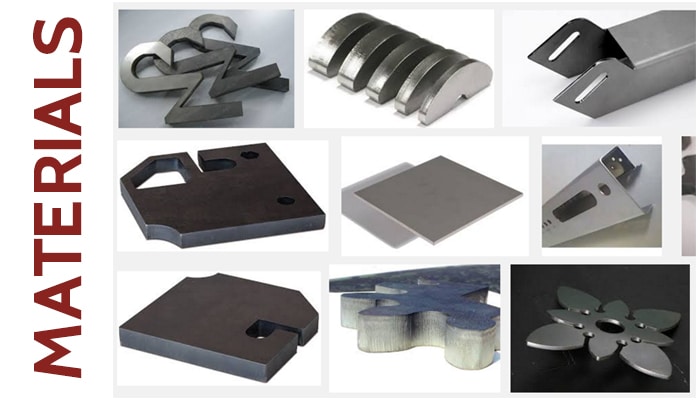

- Flexibility: 2D laser cutting is a flexible process, and this characteristic is largely dictated by the type of laser that is utilized for the application at hand. On that note, there are three main types of lasers: CO2 lasers, fiber lasers and neodymium lasers. The former two are the most popular, with CO2 being the most common due to their lower power usage, efficiency and ability to cut through a range of materials such as wood, plastic, foam, glass, acrylic and most paper-based materials. Fiber lasers work best with metal and plastics and are best used for laser marking purposes. Neodymium lasers have a smaller wavelength, and are best utilized when there’s the need to cut through thicker materials. However, because neodymium lasers are generally much more powerful than fiber and CO2 lasers, parts of such machines tend to wear and require replacement routinely.

- Pristine surface finish: In many manufacturing processes, after a prototype is made or a product run is completed, the finished parts must go to post processing to be finalized. That’s not the case with 2D laser cutting, as the process is able to leave edges with high-quality surface finishes, largely eliminating the need for post processing.

- Speed: Whether you’re purchasing a 2D laser cutting machine to move operations in house or you’re contracting out with a supplier for your laser cutting needs, one thing is certain – the process is fast. Part of this speed is because there’s no tooling required with it at the beginning and there’s no post processing required at the end. Another factor that contributes to the speed are the characteristics of the process itself (i.e. fast changeover). The bottom line is that with 2D laser cutting, parts can be created in days, not weeks, keeping operations ticking and delivery on time.

While the aforementioned are some of the main highlights of 2D laser cutting, there are a variety of other benefits associated with the technology. For instance, there is unlimited cutting paths. Changeover is also very rapid, another factor that contributes to the minimal downtime and increased efficiency associated with the process. It’s also a process that is suitable with both roll and sheet-fed materials. As we noted previously, the application potential is vast. Aside from the likes of tube cutting, the process is being used to create decor, signage, for fashion elements and even business cards.

Get your FREE eBook today by clicking on the cover image below!

Contact Troy Laser today to learn how 2D laser cutting can be utilized for your next application.