You likely already know that 2D laser cutting is a very fine, precise manufacturing process – able to achieve high tolerance cuts in a quick manner. Via the process, the high-powered laser involved is able to make cuts in a way where there’s virtually no distortion, thus eliminating the need for post-processing in the majority of applications. But one thing that you might not know about 2D laser cutting is the vast amount of materials that it can be used with, from metals to woods to even glass. This post is designed to further identify the materials that the process works with:Advances in lasers’ power, improved cutting speeds and edge quality, and lower operating costs have opened more avenues for small business use of the technology for production. Gains in power, speed, and laser beam quality during the past decade have helped smaller manufacturers use the systems in more areas, and better beam quality also reduces the need for secondary operations.

2D Laser Cutting: Most Popular Materials

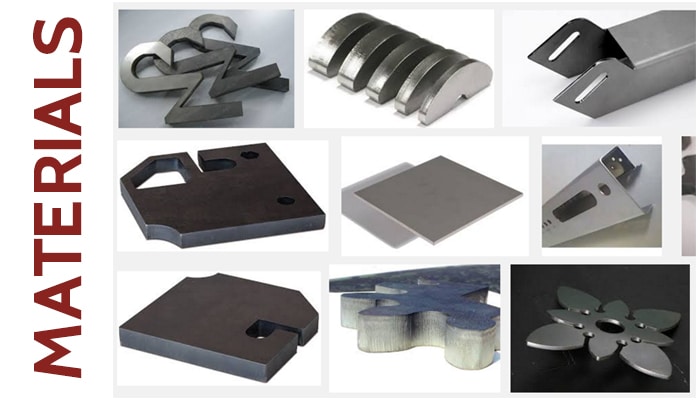

The most popular family of materials that the 2D laser cutting process works with is metals, so it’s fitting that virtually all different types of metals can be cut. The three most popular metals, however, are stainless steel, aluminum and mild steel. Here’s a closer look at these three popular metals:

- Stainless steel: Popular stainless steel products processed via 2D laser cutting include things like knives, scalpels, implants and stents. The process is generally used to cut through thicker materials where die cutting is unable to produce tolerances that are tight enough.

- Aluminum: Aluminum is a suitable material to be cut with 2D lasers, however one important note is that normally a higher powered laser is required, compared to laser cutting with other metals.

- Mild steel: Gears, chain links and coverings are just a sample of the applications that are usually processed with 2D laser cutting from mild steel.

Aside from the three most popular metals mentioned above, there are a variety of others that can be processed with 2D laser cutting. Precious metals, such as gold, silver and platinum, for instance, are suitable with the process. Titanium and titanium alloys are other suitable metals, as is copper, nickel, zirconium, zinc and tin.

A more recent material that 2D laser cutting has become suited for is glass – and laser cutting has become a suitable, more effective method than traditional manual methods of shaping and manufacturing glass products (i.e. diamond scribing and breaking). Drinking glasses and smartphone screens are just two of the many applications involved with glass material in this arena of laser cutting.

Other Materials Applicable to 2D Laser Cutting

Aside from the metals – and glass – there are many other items that 2D laser cutting works with. For instance, two of the most popular are diamonds and plastics. Diamonds are cut via a process called “sublimation,” where the diamond material is melted through the laser’s energy and then evaporated, all without going through the liquid stage. When it comes to plastics, plexiglass and thermoplastics are the key materials typically processed, with end product examples including light-up advertising pieces, among others.

Other materials applicable to 2D laser cutting include wood, paper, ceramics, textiles and labels and foils.

The 2D laser cutting process has a lot of benefits, many of which you’re already likely familiar with. But an additional competitive advantage the laser cutting process has compared to other types of manufacturing methods is the vast amount of materials that it can work with.

Looking for a team that understands Laser Cutting and Tube Laser Cutting to help you with your next project?

GET YOUR FREE ESTIMATE TODAY!