Laser cutting is fast and productive

Laser beam cutting outperforms conventional cutting systems in terms of speed, throughput and productivity. Today, laser cutting can be done much easier and faster than ever before and is used in a wide range of applications and industries. Like all tools, laser cutters have strengths and limitations. Understanding and designing for them will allow you to exploit the former and minimize the latter. At the same time, I believe clever design can turn a tool’s limitations into opportunities.

Laser cutters have a lot going for them.

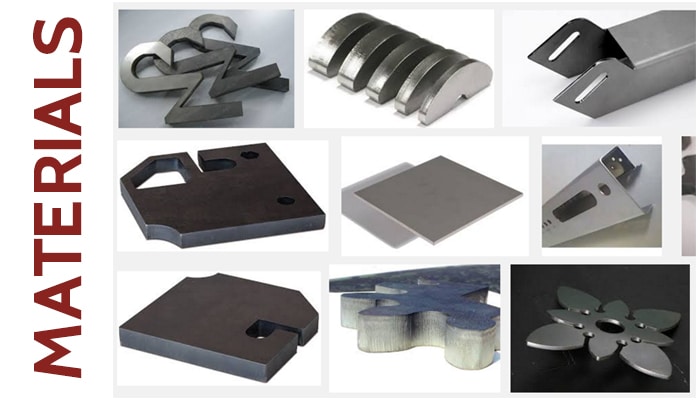

Their incredible engineering allows them to cut and etch with an accuracy measured in thousandths of an inch. With some careful measuring, this allows for the production of very accurate parts and perfect fits. They can cut out the same shape all day long and do so with incredible repeatability. Besides accuracy, their ability to cut complex shapes easily is something else they’re known for. A laser cutter is a machine that uses a laser to cut and engrave material. These machines now being used in industrial manufacturing, but also in small businesses and for personal use. Want to add some depth and that extra edge to your artwork? See exactly what laser cutting is capable of.

The best way to describe how our lasers work is to compare the system to your printer. Using similar technology, we take the images you typically print to paper, but instead we fire a CO2 laser beam that engraves and cuts your design on a wide variety of materials. Lasers are just so versatile! It is fantastic what can be done with clever design, good material selection, highly trained laser operators and the best in laser machinery. We’re continually blown away by client designs and can’t wait to see what will come in next, so why not browse the website photo gallery for inspiration, then tell us your ideas and we’ll work with you to see how it can be done! To learn more, contact Troy Laser.