Laser cutting is a little-known aspect of manufacturing that is growing considerably for small business owners and urban manufacturers. Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated..

Advances in lasers’ power, improved cutting speeds and edge quality, and lower operating costs have opened more avenues for small business use of the technology for production. Gains in power, speed, and laser beam quality during the past decade have helped smaller manufacturers use the systems in more areas, and better beam quality also reduces the need for secondary operations.

Lasers are one of the coolest technologies on the planet

Until recently, most people thought laser cutting was largely only in the hands of scientists, doctors (eye surgeries), and other specialized technology types. Much of the billions in this statistic are made up of large systems for large manufacturers, but many maker companies know the value of a laser cutter or laser engraver. They are far more accessible these days and companies like Troy Laser are ready to help. We are in the midst of making things with it and learning a ton about laser cutting and engraving.

What’s cool about a laser system?

Laser cutting systems are growing in popularity and awareness for smaller companies. If you have wanted to prototype your own creations, a laser cutting company is your answer. Laser technologies for cutting and welding parts have been steadily refined since the laser was invented some 50 years ago. Today, laser technology is easily used to quickly cut 2-D or 3-D sheetmetal parts and to make high-quality welds. The flexibility of lasers has led to adoption of robotic laser processing and five-axis laser cutting and welding in many areas, including cutting the newer high-strength steels in today’s automobiles and cutting and welding processes used in medical device manufacturing. Laser cutting is a manufacturing process which can eliminate the need for machining on many engineering jobs, enabling you to save money on manufacturing costs.

So, now you can see why Laser Cutting is super cool. Laser cutting also presents certain advantages over plasma cutting as this process is more precise and uses less energy when cutting steel and aluminum sheets.

Here are a few advantages from Laser Cutting:

Laser cutting has many benefits when it comes to production of parts and products.

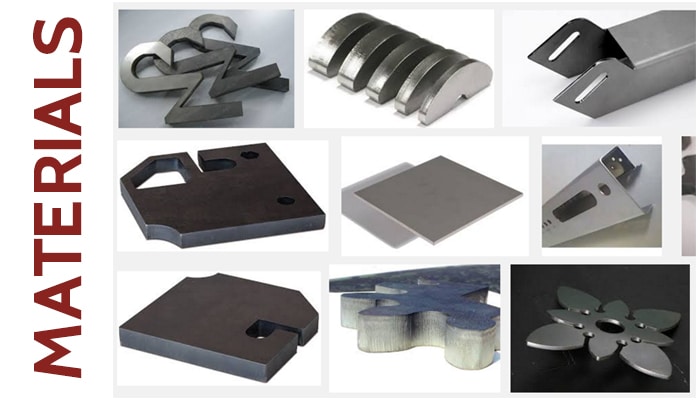

- Capable of cutting many materials and thicknesses

- Cutting narrow kerf widths, which promotes efficient part nesting, yielding better sheet utilization and material savings

- Fast

- Easily and accurately repeatable

- Reliable

- Reduced time for set-up with the ability to react and adapt quickly to changing production needs that are market or quantity driven

- Efficient processing, as multiple jobs or parts can be nested and cut in a single program.

- No secondary clean up process required for most materials, and is usually ready for immediate shipment

To learn more about Laser Cutting and how your small business can benefit, please contact Troy Laser. We are Michigan’s premier specialist in laser cutting, with a combined 35+ years experience in laser cutting, manufacturing, and handling any production tool in Warren, MI.