Companies seeking Michigan manufacturers to help with custom parts or higher quality part output typically will consider laser cutting or water jet cutting. Depending on the type of material used and the desired end result, one of these two methods may be appropriate for a given application. First, it is helpful to examine the fundamental differences between the processes and the materials being used.

Laser Cutting

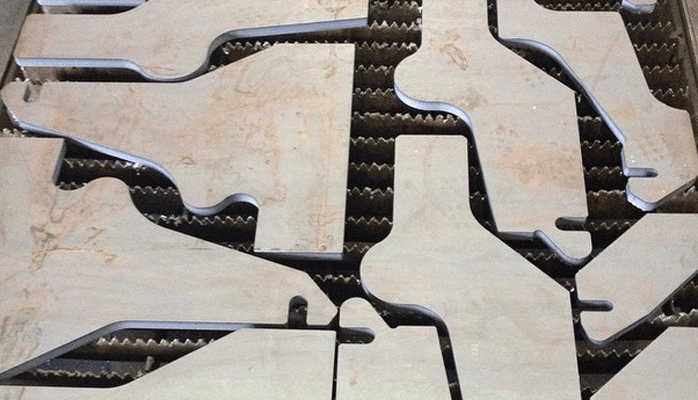

A laser cutter relies on a gas laser, such as a CO2 laser, for energy. The CO2 is then transmitted through a beam, which is guided by mirrors, and directed at the material. With CO2 lasers, the laser source is located inside the machine and the beam can output between 1500 and 2600 Watts. Materials and applications, as well as precision and safety, are important factors to think about when considering laser cutting.

Laser Cutting Materials and Applications

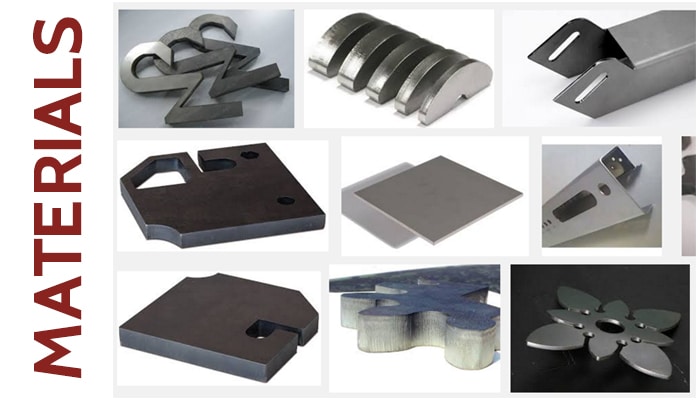

Laser cutters work well with a variety of materials including, plastic, glass, wood, and all metals (except for reflective metals).

You should consider laser cutting for your custom parts if:

- You want to create a new and innovative project

- You care about precision – including surface and edge face quality

- You want to lower the risk of damaged parts and contamination of the final product

- You want the best possible product with the fastest turnaround

Water Jet Cutting

Unlike laser cutters, water jet cutters use pressurized water to cut material. To increase cutting ability, abrasives such as garnets and aluminum oxide are often added. The overall process mimics erosion in nature, just at a much higher speed and concentration: a high-pressure pump drives the water through rigid hoses, resulting in a forceful water jet—a typical water jet can output between 4 to 7 kilowatts. Unlike a laser cutter, where the laser source is located inside the machine, the work area and pump are often separate.

Water Jet Cutting Material and Applications

Water jets can cut virtually any material including combination materials—with combination materials, however, water jets pose the threat of delamination. They can sometimes handle 3D material cutting, and exhibit limited ability with sandwich structures and cavities. Cutting materials with limited access is possible, but difficult. Water jets usually perform cutting, ablation, and structuring, specifically with materials like stone, ceramics, and thick metals. Materials that range in thickness between 0.4” and 2.0” benefit from water jet cutting.

Water Jet Cutting Environmental Considerations:

The waterjet cutting process can generate up to 2 GPM of overflow water from the cutting tank. Local regulations may require this overflow water to be processed before being released into the drainage system.

To learn more about Troy Laser and how our team of experts are breaking the mold when it comes to making changes in something established, especially by introducing new methods, ideas, or products, click here to speak with a team member or request a quote.