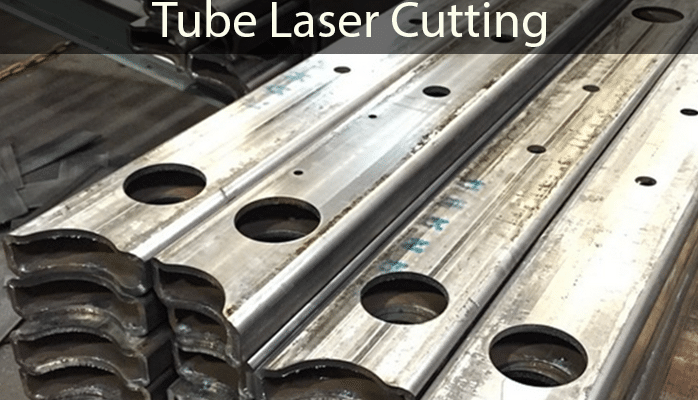

Speed up production and reduce costs

The Tube Laser gives designers freedom to easily put any cutout shape into pipe and tubing. Besides eliminating the old drill and saw, this new technology allows for error proof constructing techniques that speed production and reduce cost. With Tuber Laser Cutting, you gain the ability to hold tight tolerances on complex laser cut geometry yields precision components ready for assembly, welding, finishing, and fabrication.

DID YOU KNOW?

Tube Laser cutting is a relatively new manufacturing process when compared with other manufacturing processes which have their origins from the industrial revolution.

Accurate method of cutting

Tube laser cutting works on a multi-axis basis where the tube is rotated by a large chuck and the laser then cuts the necessary holes, apertures and profiles. This is a highly accurate method of cutting metal tube and has many advantages over traditional “sawing” methods.

The advantages of using tube laser cutting profiles are:

1. Repeatability: When cutting tube by hand it is often the case that there are differences from part to part as the operator may use slightly different methods each time.

2. Speed: Lasers cut at multiple meters per second and can cut tube hundreds of times faster than via manual methods.

3. Versatility: The flexibility of laser profiling tube gives far more options for designers of parts especially in the architectural and construction sectors. Complex designs can be cut into a tube which are not possible by traditional cutting methods.

4. High Volume Manufacturing: The standard supply of steel tube is in six meter lengths, managing these lengths in traditional factories was cumbersome.

In summary tube laser cutting uses the same techniques as flat laser cutting apart from the vital difference of the tube rotating as cut. There are many advantages over traditional tube cutting methods, however, the most important advantage is that it saves time and money in manufacturing – This is vital in today’s competitive manufacturing marketplace.